1-1/8” D Handle Rotary Hammer

Model: DG 2805-D

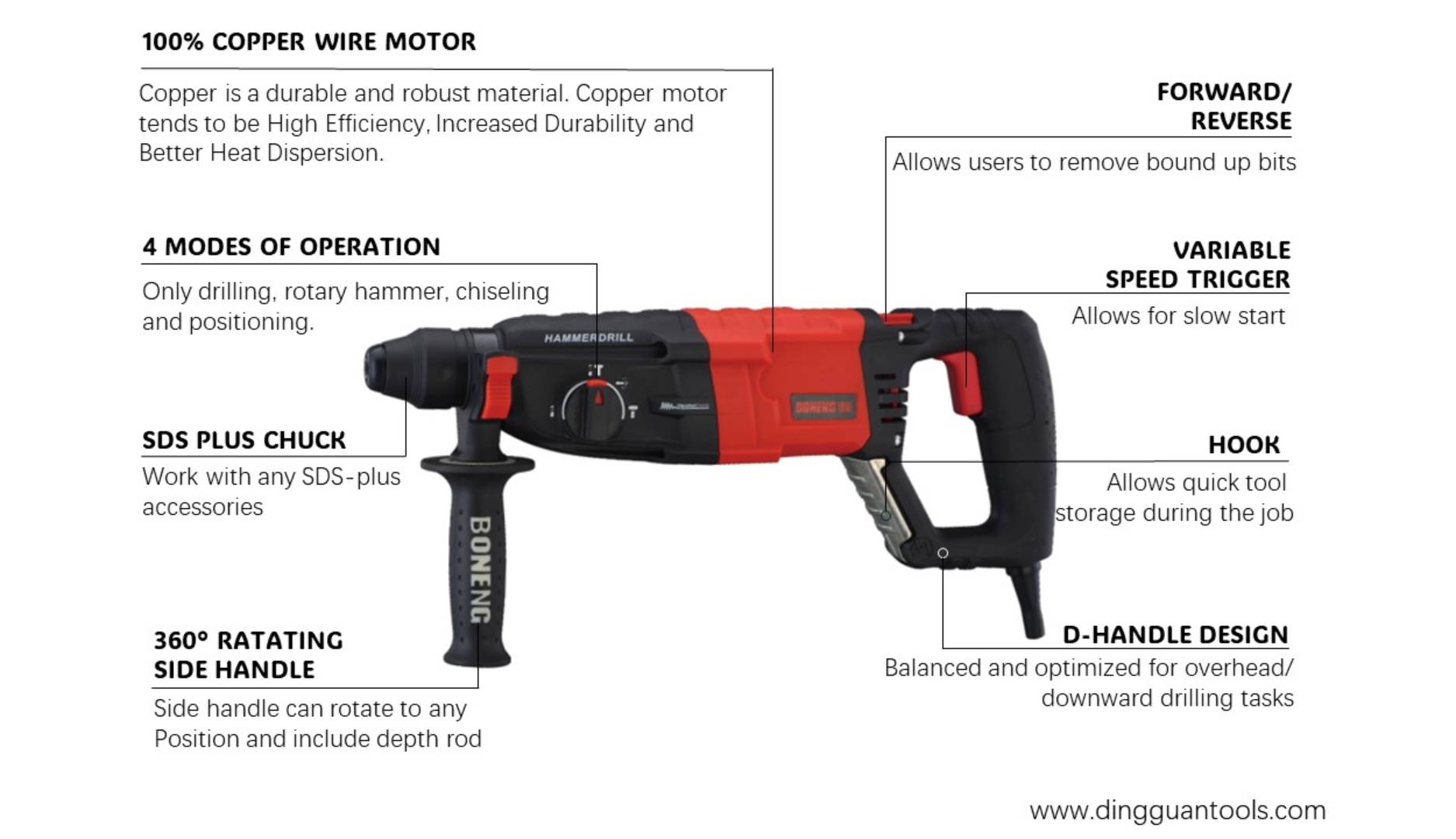

**SDS-plus System- tool free bit changes with automatic bit locking.

**D-handle Design- balanced and optimized for overhead/downward drilling.

**Hammer Hook – allows quick tool storage during the job

**KickBack Control – to stop tool rotation once bit bind-up situation occurs

Get Latest Price

Specification

| Input Power | 850 w |

| No-load Speed | 0-1300 rpm |

| Impact Rate | 0-5800 bpm |

| Barely Tool's Weight | 3.2 kg |

| Max Drill Diameter | ø13mm in Steel; ø28mm in Concrete; ø32mm in Wood |

Descriptions

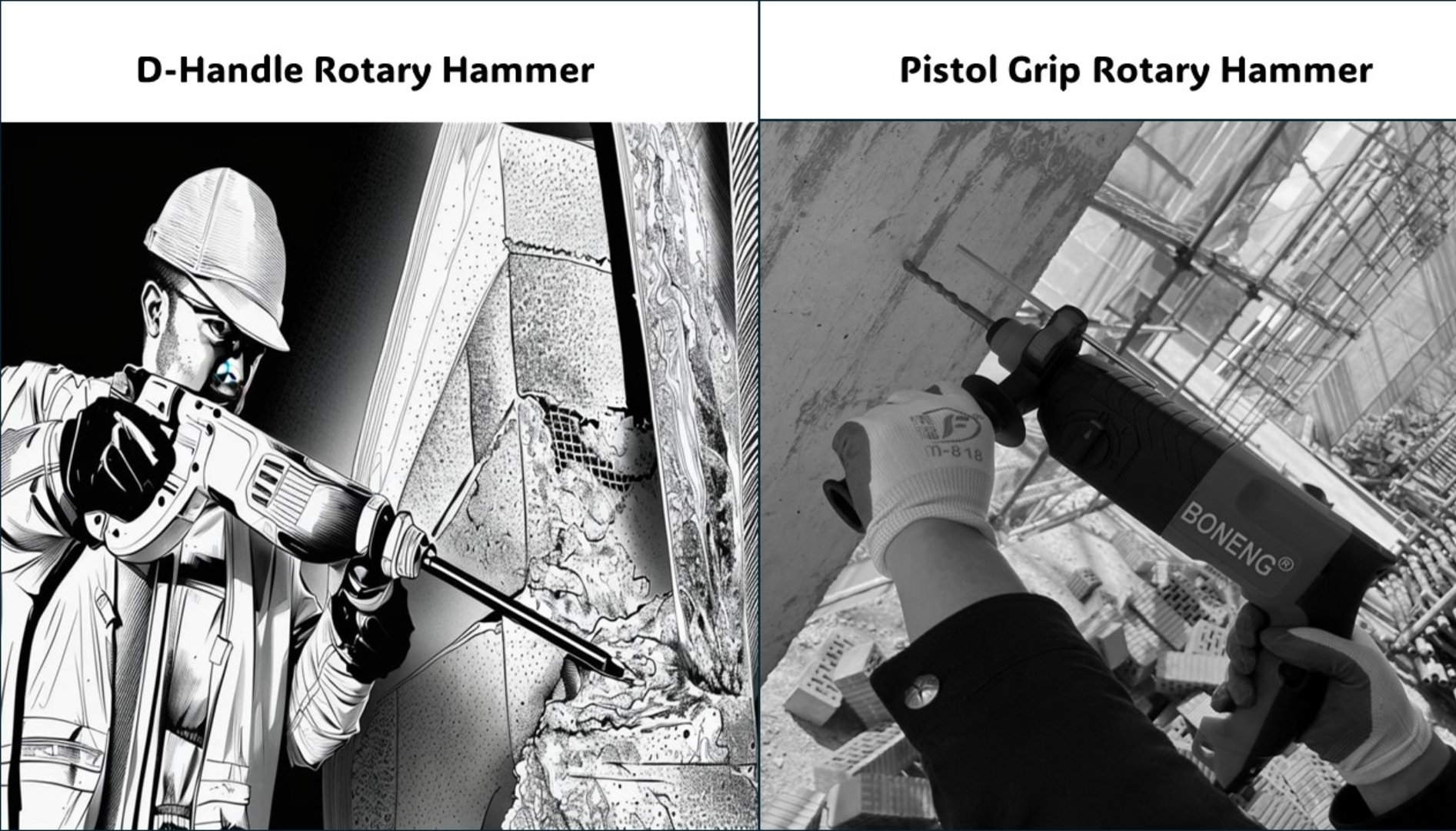

What’s the difference between D-handle rotary hammer drill and pistol grip rotary hammer?

D-handle rotary hammers are optimized for overhead and downward drilling primarily due to their ergonomic design and the distribution of weight, providing better control and comfort in these specific drilling tasks. Here are some reasons why D-handle rotary hammers are well-suited for overhead and downward drilling:

1.1**Ergonomic Design:**

- The D-handle design allows for a comfortable and ergonomic grip, providing better control and reducing strain on the user's hand and wrist. This is particularly important when working overhead or in downward positions, as it helps maintain accuracy and minimizes fatigue during extended use.

1.2 **Improved Balance:**

- D-handle rotary hammers typically have a well-balanced weight distribution, with the handle located at the back of the tool. This design helps offset the weight of the tool and provides improved balance, making it easier to control during overhead or downward drilling tasks.

1.3 **Enhanced Stability:**

- The D-handle, when held with a firm grip, offers enhanced stability and control. This is crucial when drilling vertically or in positions where maintaining stability is challenging. The handle allows users to exert downward force with better precision.

1.4 **Optimized for Vertical Applications:**

- The D-handle configuration is particularly beneficial for vertical applications, such as drilling into walls or ceilings. The user can position the tool more comfortably and maintain better control over the drilling process.

1.5 **Reduced Fatigue:**

- The ergonomic benefits of D Handle Rotary Hammer contribute to reduced user fatigue. Overhead and downward drilling can be physically demanding, and a well-designed handle helps manage the tool more effectively, allowing for longer periods of use without excessive strain.

1.6 **Better Alignment:**

- The D-handle allows users to align the rotary hammer more easily with the drilling surface. This is crucial for achieving precise holes, especially when drilling vertically or at angles.

1.7 **Versatility in Applications:**

- D handle rotary hammers are versatile and suitable for various applications, including overhead and downward drilling. The design ensures that users can adapt the tool to different orientations without sacrificing control or comfort.

While D-handle rotary hammers excel in overhead and downward drilling scenarios, it's important to note that their design may not be as well-suited for horizontal or forward drilling compared to pistol grip models. Users should choose the handle design based on the specific nature of their drilling tasks to optimize comfort, control, and overall performance.

What's the benefits of using 100% copper wire motor for rotary hammer?

Using a 100% copper wire motor in a rotary hammer comes with several benefits, primarily related to performance, durability, and overall reliability.

Here are the key advantages:

2.1 **Higher Efficiency:**

- Copper is known for its excellent electrical conductivity. A 100% copper wire motor enhances the efficiency of the electrical system, ensuring that more power is effectively converted into mechanical energy. This can result in improved overall tool performance.

2.2 **Increased Durability:**

- Copper is a durable and robust material. Motors wound with 100% copper wire tend to withstand the rigors of frequent use and challenging working conditions better than those made with other materials. This contributes to the longevity of the rotary hammer.

2.3 **Better Heat Dispersion:**

- Copper has superior thermal conductivity compared to other materials used in motor windings. This property helps dissipate heat generated during operation more effectively. Reduced heat buildup contributes to the prevention of overheating and extends the motor's lifespan.

2.4 **Consistent Power Output:**

- Copper's conductivity also ensures a more consistent and stable flow of electrical current. This results in a more reliable and steady power output, which is crucial for maintaining optimal performance during demanding tasks.

2.5 **Reduced Energy Loss:**

- Copper minimizes energy loss in the form of heat. A motor with 100% copper wire windings experiences lower resistance, meaning that less electrical energy is converted into heat. This efficiency leads to better power utilization and performance.

2.6 **Resistance to Corrosion:**

- Copper is resistant to corrosion, which makes the motor more resilient in various environmental conditions. This resistance helps protect the internal components of the motor and contributes to the tool's long-term reliability.

2.7 **Suitability for Heavy-Duty Applications:**

- D Handle Hammer Drills are often used in demanding applications, such as drilling into concrete or masonry. A motor with 100% copper windings is better equipped to handle heavy-duty tasks without experiencing significant wear or performance degradation.

While the initial cost of a tool with a 100% copper wire motor may be higher, the long-term benefits in terms of performance, durability, and reliability can make it a worthwhile investment for users who require a robust and dependable rotary hammer.

Compared with cordless SDS Hammer Drill, what's the benefits of corded one?

Corded rotary hammers and cordless rotary hammers each have their own set of benefits, and the choice between them depends on the specific needs and preferences of the user. Here are some advantages of corded rotary hammers compared to cordless ones:

3.1**Continuous Power:**

- Corded rotary hammers have a constant and uninterrupted power supply as long as they are connected to a power source. This ensures that the tool can operate continuously without interruption, making them suitable for extended or heavy-duty tasks.

3.2 **No Battery Limitations:**

- Corded tools don't rely on batteries, eliminating concerns about battery life, charging times, or the need to carry additional batteries for extended work periods. This makes corded rotary hammers well-suited for tasks that require sustained power.

3.3**Consistent Performance:**

- Corded tools generally deliver consistent performance throughout the operation since they draw power directly from the electrical source. There's no gradual loss of power as the battery depletes, ensuring reliable and uniform results.

3.4 **Higher Power Output:**

- Corded rotary hammers often provide higher power output compared to cordless models. This can be advantageous when dealing with tough materials such as concrete, where more power is beneficial for efficient drilling or chiseling.

3.5 **Lighter Weight:**

- Without the need for heavy batteries, corded rotary hammers can be lighter and more maneuverable. This can be an advantage for users who prioritize tool weight and handling during extended periods of use.

3.6 **Cost Efficiency:**

- Corded tools are generally more cost-effective upfront compared to cordless tools. Users don't need to invest in expensive battery systems or worry about replacing batteries over time.

3.7 **Ideal for Stationary Tasks:**

- If the D Handle Rotary Hammer will primarily be used in a fixed location near a power source, a corded model is often more convenient. There's no need to carry and manage a battery, making corded tools suitable for stationary tasks.

While corded rotary hammers offer these advantages, it's important to note that cordless models have their own merits, including portability, flexibility, and the absence of a power cord. The choice between corded and cordless rotary hammers ultimately depends on the user's specific requirements and the nature of the tasks at hand.

What's the difference between quick release chuck and standard SDS chuck

Related Products

FAQs

Frequent Asked Questions for Placing an Order

Q: What quality do you supply ?

Q: What's the minimun quantity of order do your factory take?

Q: How long will it take for order production.

Q: What's kind of warranty do I have?

Get In Touch With Us

Committed to providing Reliable, Powerful and Extrme Long service life conceret tool for mansons, carpenters, remodelers,electricians, maintenance crews in various projects. Such as interior renovation, construction or road construction.

Tel: +86 15355628697

Tel: +86 15355628697

Email: alva.pan@tzboneng.com

Email: alva.pan@tzboneng.com

Add: NO.4 Fengjiang Rd,Luqiao,Taizhou City, Zhejiang, China

(Z.P. 318000))

Add: NO.4 Fengjiang Rd,Luqiao,Taizhou City, Zhejiang, China

(Z.P. 318000))

Inquiry Now

Please give us a message for your enquiry order or advice.

Send Message